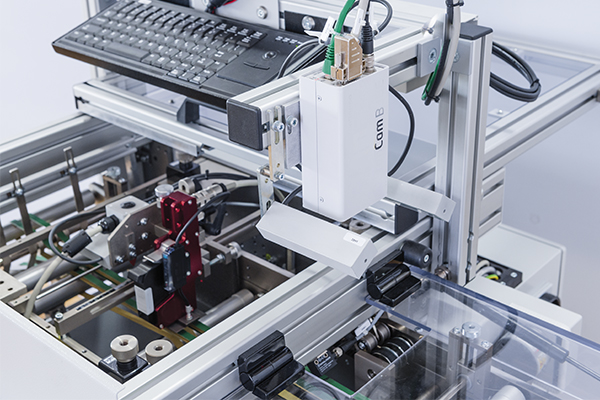

Camera measuring system for automatic 100% quality control of folded products such as outserts

This high-precision inspection and ejection unit has been specially developed for the quality assurance of OUTSERTS in production. It combines state-of-the-art measurement technology with user-friendly operation and ensures reliable monitoring and ejection of non-conforming products - fully automatically and without computer operation during the ongoing production process.

The identification and position reading of each individual OUTSERTS takes place in real time, while the overhang and angle are checked precisely at the same time. The integrated net counting function enables precise recording of good products, while products outside the tolerance limits are reliably detected and ejected. If glue monitoring is activated (optional), products are also ejected immediately in the event of tolerance deviations.

A clear evaluation of the measurements provides transparency about the production quality at all times. The reliable separation into i.O. (in order) and n.i.O. (not OK) products is ensured by an intelligent reject system. All rejected products are reliably collected in a separate collection container.

The OUTSERTS are mechanically aligned and laterally compacted for optimum product guidance by means of a smooth push in throughfeed. Thanks to the integrated additional lighting, precise detection is guaranteed even in difficult lighting conditions.

Simple programming via a PC adapter enables quick and user-friendly configuration. Up to eight different product programs can be saved directly in the system and called up at any time - ideal for frequent product changes. The spindle drives also allow the unit to be quickly and precisely adjusted to new formats.

The inspection and discharge unit can be seamlessly integrated into the existing MV transport line and is immediately ready for operation. The triggering can also be easily adapted to different production conditions.

This solution offers maximum process reliability and efficiency - for consistently controlled OUTSERT production at the highest level.

Coding & serialization module

Prints individual codes on each finished folded product (e.g. OUTSERTS) as a track & trace option

The new TTM module smoothes the outserts/booklets in the infeed by lateral jogging

A unique and individual code imprint or serialization for each finished folded product is applied using an inkjet print head in a throughfeed process

A built-in camera verifies each print and checks that it is perfectly legible. Print quality parameters (e.g. sharpness, contrast, alignment, etc.) can be checked individually to ensure that the products are legible in the Track&Trace process.

A reject device separates faulty products, e.g. if they do not meet the quality specifications.

The print head is designed for industrial applications and can produce variable print images and also print 1- and 2-dimensional codes (Pharmacode, Datamatrix, QR codes, etc.).

Maximum code height 12.7 mm and the maximum resolution is up to 600 dpi (depending on speed)

The TTM module is plug&play capable and can be easily integrated into a GUK-Vijuk MV-11 Outsert system at any time or combined off-line with the new GUK PA15 dispensing feeder.

Quick-change cartridge with integrated print head and layout change via file transfer makes set-up quick and easy

Cartridge replacement ensures a dirt-free work area and flawless print nozzles

The ink is quick-drying and reliable

UV equipment can also be used as an option: UV inkjet printing and camera reading with special white/UV illumination and special filter device (can still be used with black ink)

Style

CM, TTM or a combination of both = CTM

Speed

max. 130 m/min

Style

TTM: in-line or offline (e.g. in conjunction with booklet feeder PA 15)

Formats

CM module: Special smooth pusher adjustable from 30 - 150 mm

Platzhalter

Platzhalter

Platzhalter

Platzhalter

Platzhalter

Platzhalter