A good feeding system for the folded material is crucial for an optimum folding result. We offer our sheet feeders in different performance classes and with properties that are perfectly matched to the machine type .

The R6 round pile feeder offers continuous production without stopping the machine to load the feeder.

Available in working widths of 43, 53, 54, 73 and 74 cm.

A maximum sheet length of 144 cm also offers plenty of space for long sheets. With suction rollers that are freely accessible from above.

All operating elements are freely accessible from the outside.

Control panel at eye level and higher loading table make the feeder particularly convenient to operate!

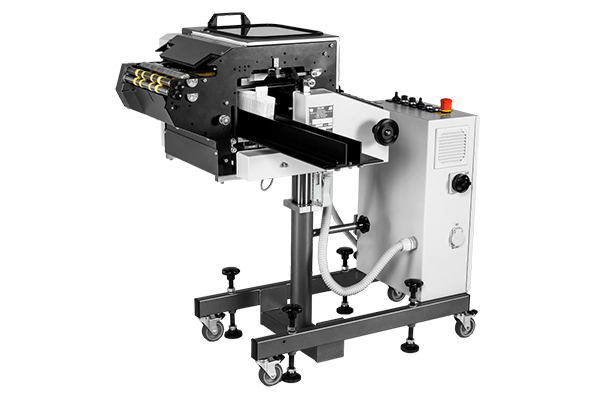

The flat pile feeder is a high-performance sheet feeder.

FL2

Our small FL2 flat pile feeder offers very fast sheet separation and high performance. In combination with machines from the 35/36/43/45/50 model series, this feeder with its simple and clear control system has the best performance values.

Also available as a solo feeder with independent control.

The optional pre-stacking trolley enables the feeder to be filled quickly

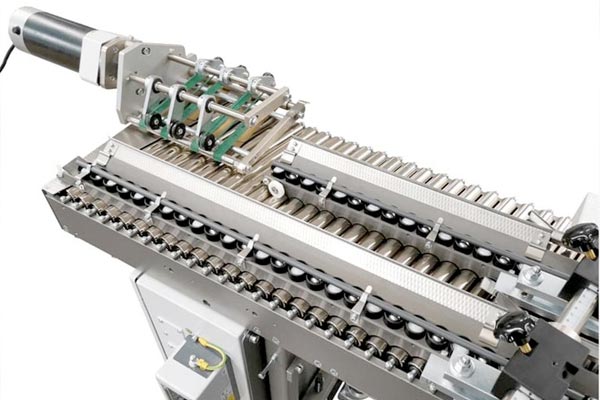

FL3

Available in widths of 54 cm or 74 cm.

Equipped with the L5-Control computer control with touch operation, the feeder offers high performance and reliable sheet separation thanks to a separating head with automatic height control. This ensures precise sheet separation even with uneven pile surfaces.

High sheet output thanks to pneumatically controlled suction cup, whose suction effect is switched off by the suction roller when conveying starts. Sheet transport is controlled by an electronic length calculator.

The P6 pallet feeder makes it easy to load sheets of paper directly onto pallets. There is no need for restacking and the feeder is therefore particularly easy to use.

A stacking height of up to 120 cm ensures maximum utilization of capacity.

The P6 is available in 53, 54, 73 and 74 cm working widths.

A laser beam automatically facilitates stack positioning.

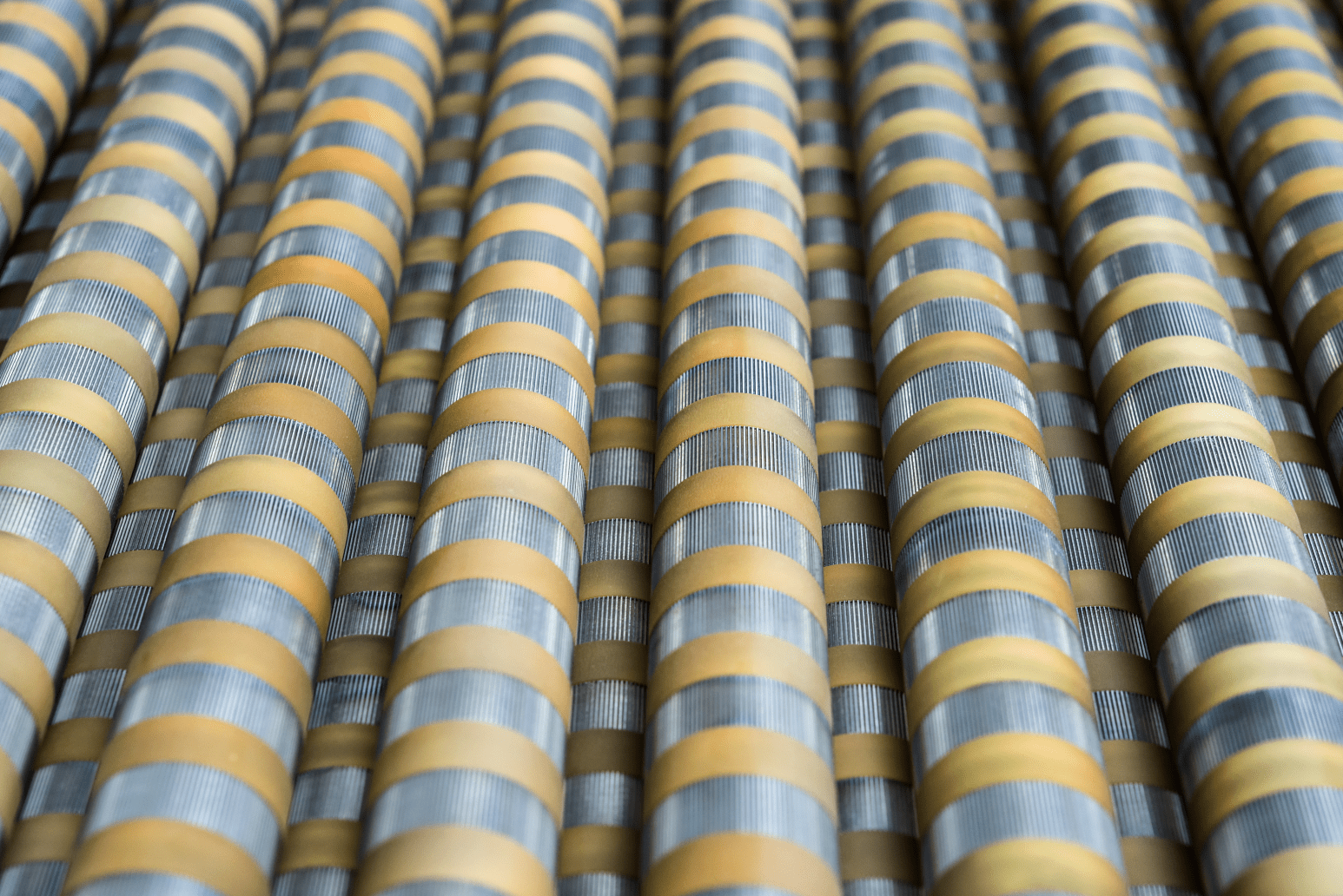

Combi folding rollers

Rubber/steel overlapping segmented rollers particularly suitable for pharmaceutical, lightweight or glossy paper applications

EK300 knife folding unit

Modular knife folding unit for cross-fold application

Glue system and camera monitoring

Blade shaft for

station 1 and so on and so forth