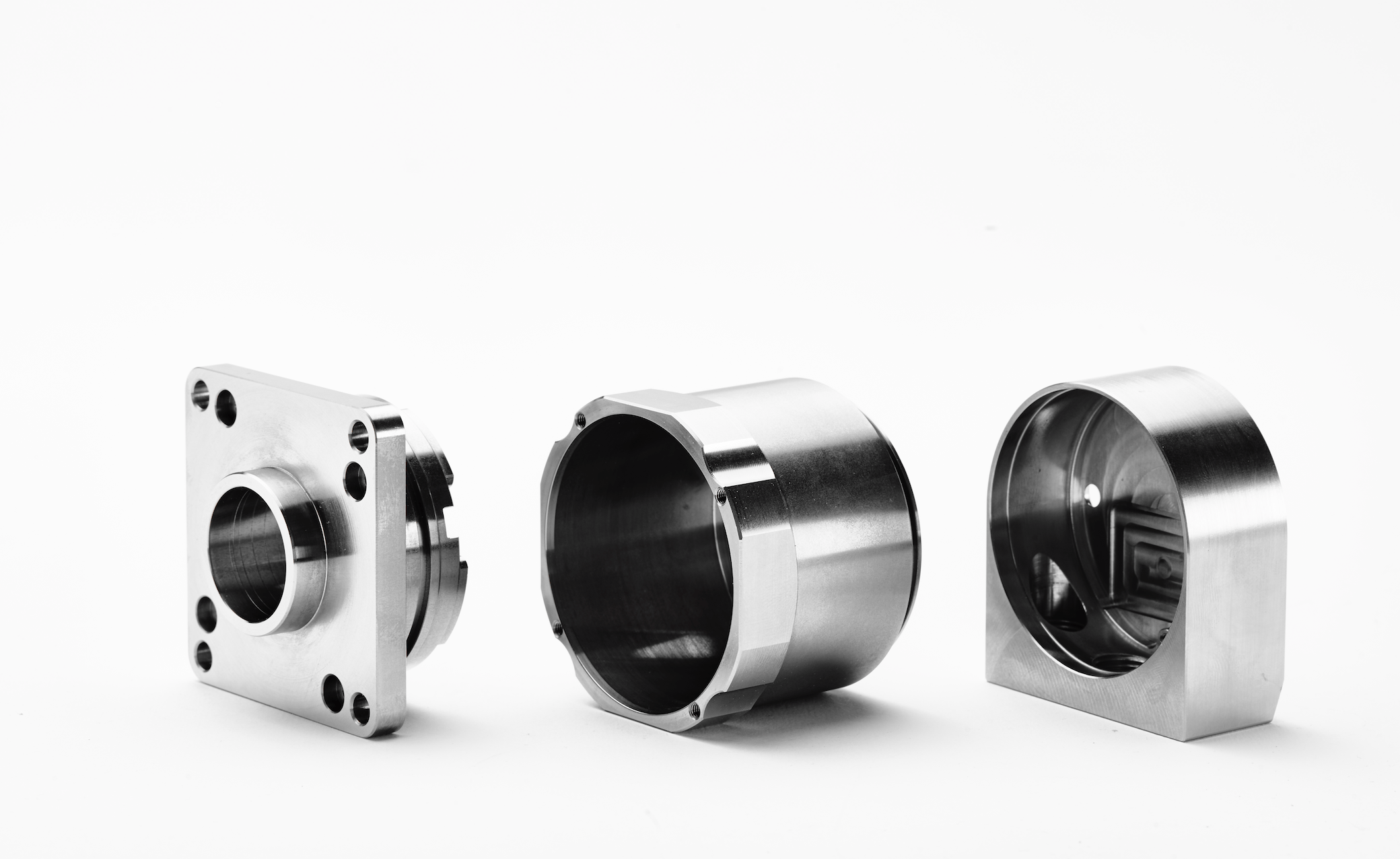

Mit über 65 Mitarbeitern produzieren wir auf rund 6000 qm Fertigungsfläche, Präzisionsdrehteile von höchster Qualität.

We focus on ready-to-install turned parts and assemblies for the metalworking industry, including the automotive and commercial vehicle industry. State-of-the-art technologies as well as committed and highly trained employees enable us to produce the highest quality with short throughput times and favorable cost structures. zu fertigen.

We produce in quantities from one to 10 million. The customer-oriented thinking and actions of our employees and certification in accordance with the

IATF 16949 and ISO 14001 standards ensure the high level of GUK quality today and tomorrow.

Professional teamwork is the key to our success. Our employees and state-of-the-art machinery develop products and services that impress our customers time and time again.

We produce ready-to-install turned parts and assemblies for all sectors of the metalworking industry from the following materials:

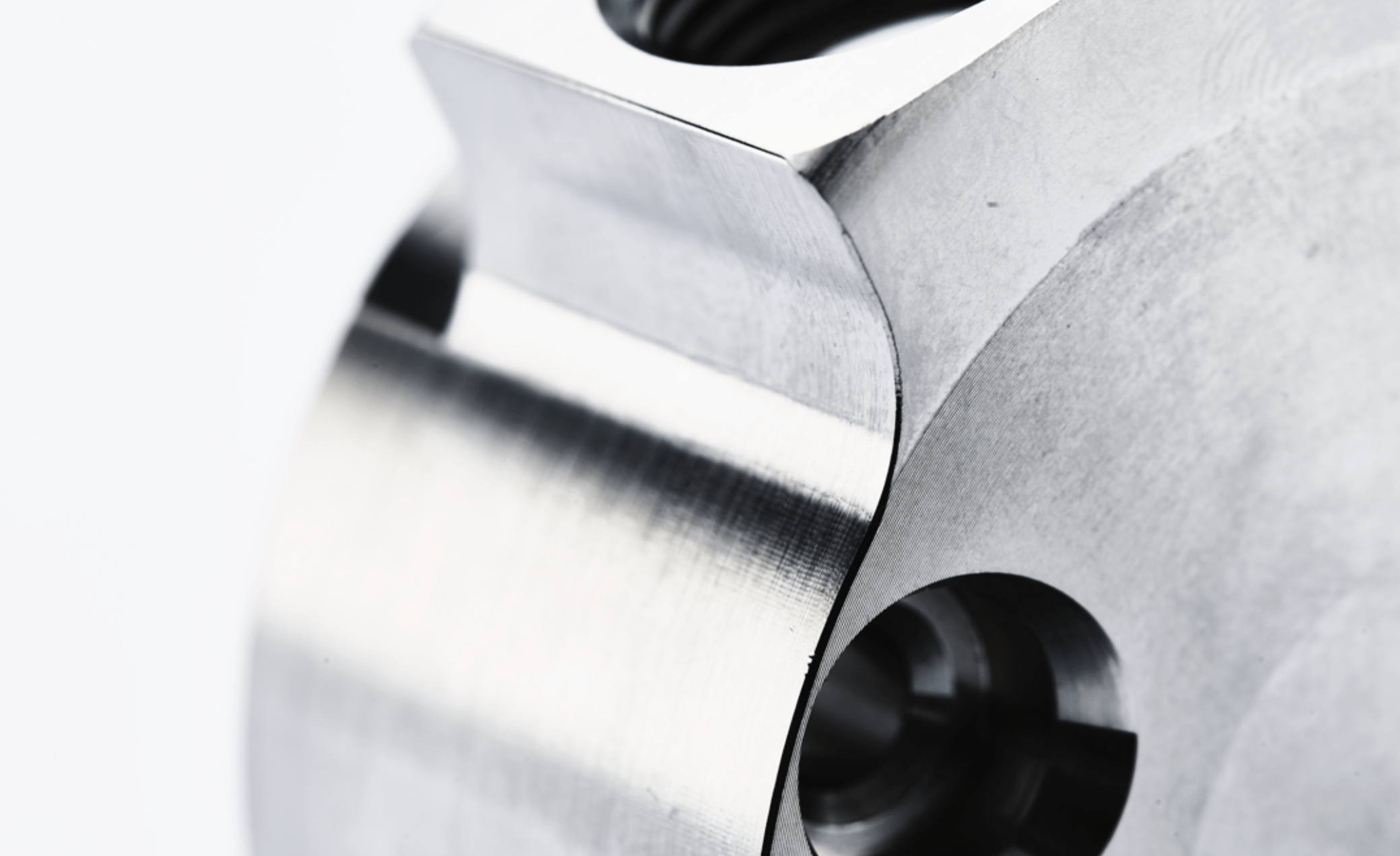

Metal cutting

Short turning from ø 5-70 mm, polygon turning,

Long turning up to max. ø 20 mm, milling, drilling, deep-hole drilling, gear milling.

Assembly

Inserting filters, additional parts or other assemblies with the manufactured turned parts.

Hard machining

Hard turning, honing, internal grinding and centerless grinding.

Mech. surface treatment

TEM and ECM deburring*, vibratory grinding and glass bead blasting, laser marking

Heat treatment

Case hardening, nitriding*. carbonitriding, tempering, induction hardening, vacuum hardening, annealing

Surface treatment*

Zinc plating, nickel plating, silver plating, burnishing, phosphating, anti-friction coating, anodizing, tuflo coating, microencapsulation

* Subcontractors performance class A

Professional teamwork is the key to our success. The good training of our employees as well as internal and external training and further education measures create a lively, up-to-date knowledge potential.

These employees and state-of-the-art machinery create products and services that continue to delight our customers.

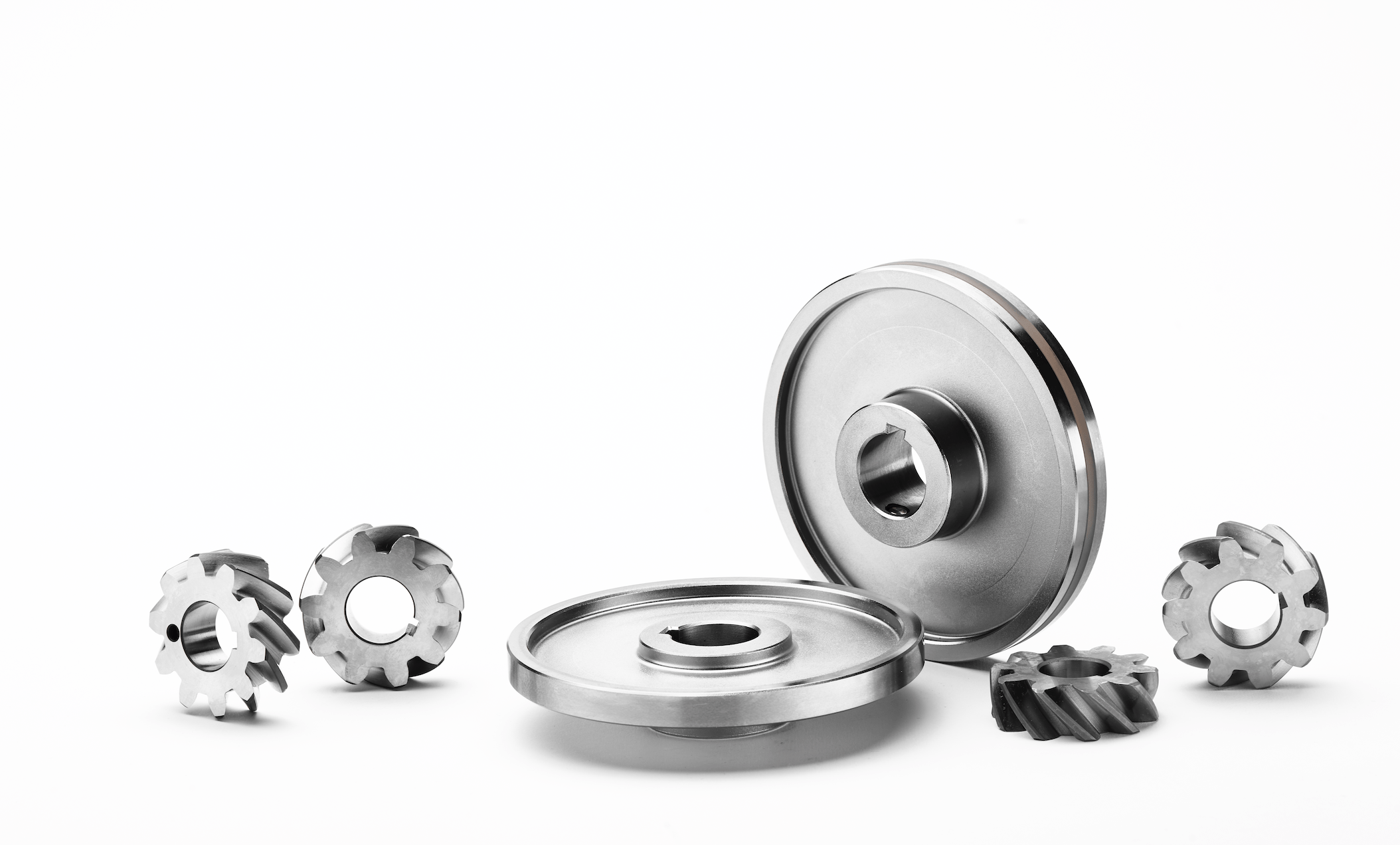

The various functional areas in our company work closely together like interlocking gears.

Turning technology

Processing technology

Sanding technology

The QM system is characterized by its compact, demand- and process-oriented structure. From incoming materials to production and product delivery, our employees check, measure and monitor the manufactured products. Sustainable use of resources and environmentally friendly processes are important to us, documented by an ISO 14001 certificate (since 2008).

Our employees' customer-oriented thinking and actions, as well as our IATF 16949 certification, ensure the GUK quality level today and tomorrow. Environmental protection is second nature to us. ISO 14001

BOSCH hat uns bereits fünf Mal in Folge für hervorragende Leistungen mit dem BOSCH-Lieferantenpreis ausgezeichnet.